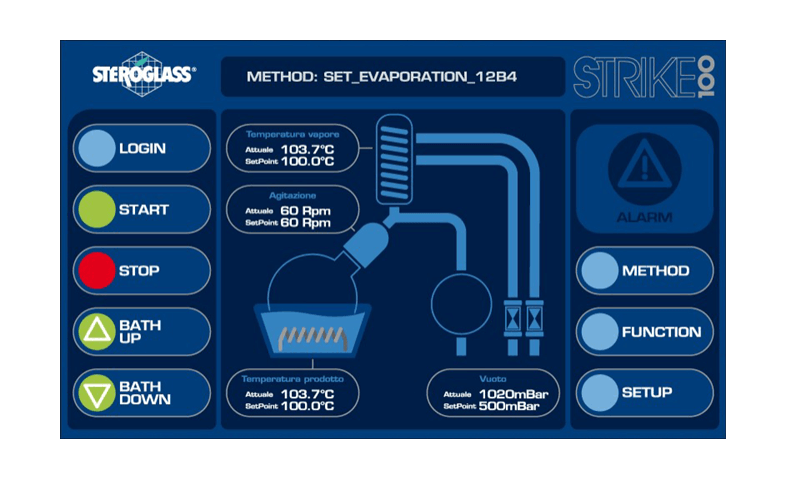

STRIKE100 is a large capacity Rotary Evaporator born for the chemistry and designed for any industrial process need.

3.3 borosilicate glass and PTFE allow aggressive substances treatment.

Works efficiently both under vacuum or any ambient conditions. 50 or 100 L evaporation flask rotation results in a forced convection and homogenous liquid distribution, preventing sedimentation.

High evaporating exchange surface is guaranteed. The sealing system ensures perfect vacuum tightness and maintenance‐free operations. Glassware can be customized to meet any client specific needs.

STRIKE20 is a 20L Rotary Evaporator (i.e. Rotovap) designed for industrial evaporation and R&D purposes suiting all the process phases.

3.3 borosilicate glass and PTFE allow solvent concentration or purification also with aggressive solvent.

Works efficiently both under vacuum and any ambient conditions. 6, 10 or 20L evaporation flask rotation results in a forced convection and homogenous liquid distribution, preventing sedimentation while ensuring high evaporation exchange surface. The sealing system enables perfect vacuum tightness. No maintenance needed.

Glassware can be customized to best meet your specific requirements.